In our modern toolshop we offer:

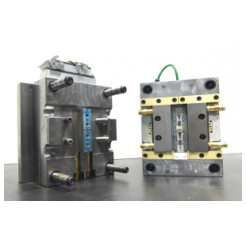

- production of complete tools/moulds for plastic injection moulding

- repair and modification of tools

- production of various assembly and setting jigs for various applications

- prototyping

- metalworking - milling, turning, drilling, grinding, electro erosion, wire cutting

The toolshop equipment is at the top level and corresponds to the high requirements of customers. The entire area is air-conditioned to a constant temperature to achieve the highest possible machine accuracy. The production hall is equipped with two cranes with a capacity of 2 and 6.3 tons for easy handling in production.

We use CAD - Autodesk Inventor and Spaceclaim to process the complete mould design, including drawings.

We are able to test the tools in our injection moulding plant.

max. tool size (mm)

800x800mm

max. tool weight

3t

toolshop equipment

Hermle C12 5-axis machining centre

- for the production of graphite electrodes

- traverse paths: 300x300x500mm

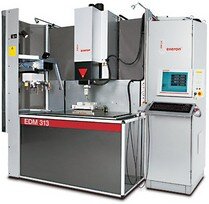

EDM erosion machine EXERON 313

- traverse paths: 620x420x400mm

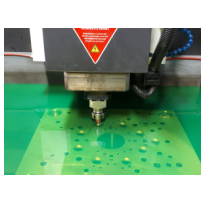

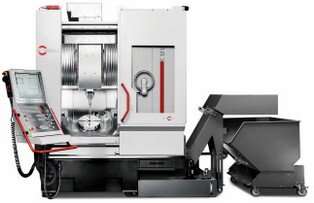

Hermle C42 5-axis machining centre

- for machining plates and shapes

- traverse paths: 800x800x550mm

Hermle C42 3-axis machining centre

- for machining plates and shapes

- traverse paths: 800x800x550mm

wire cutting machine FANUC Alpha C600iA/Z400

- traverse paths: 600x400x410mm

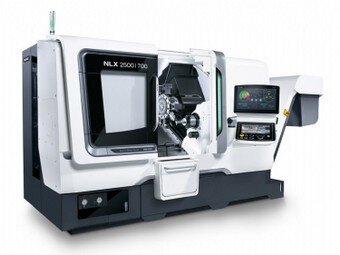

CNC lathe DMG Mori NLX 2500-700

- for the production of rotating parts

mechanical metal working machines

- column drill for deep drilling

- TRENS SU50 lathe

- 2x surface grinder

- 1x round grinder

- band saws for cutting graphite and semi-finished products

- CRONITEX micropulse welding

NC surface grinding machine ZIERSCH ZT48

spotting press Millutensil B28E

goals and plans for the future

- one of our goals is to develop cooperation with technical universities for the development and implementation of new materials (e.g. materials filled with organic fibres, materials with nanofillers,...)

- EDM centre - linking of 2 EDM machines by a robot that will operate both machines - exchange of electrodes and workpieces

measurement

- Mitutoyo LH-600E digital height gauge

- Johanson end gauges and cylindrical gauges

- calipers, micrometers,...

- Wenzel LH87 3D measurement or digital microscope if required