NEWS!

our experiences:

- assembly of assemblies for the automotive industry

- complete production of small kitchen appliances - kettles, coffee makers, toasters,...

- complete production of lamps

- electromechanical assembly - production of assemblies for headphones, vacuum cleaner parts, motor covers with fans,...

- precise pad printing

- ultrasonic welding - electronics and automotive

NEWS!

- production of moulds for plastic injection moulding

- production of jigs

- metalworking - milling, EDM, turning, grinding,...

2024 - real 2K part - without any handling

The customer asked us to help them to put the old tool back into action and to produce spare parts. It worked ;)material PBT 30%GF + TPE

end of August 2023 - we took few pictures with a drone

For the purpose of the book we took some pictures using a drone.

2023 - finishing the drying of the material

We have finished the last part of the drying of the material - it is flexible and allows the dried material to be unloaded into the carts. These can then be taken to the machine and the material can be sucked from them.

2023 - CNC lathe for toolshop

We have equipped the toolshop with a new CNC lathe DMG MORI NLX 2500-700

2022 - central drying and transport of material

We have extended the central drying and transport of material so that we have almost all machines covered.We started an electronic documentation project to reduce paperwork.

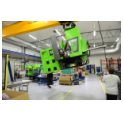

2021 - FANUC full-electric injection moulding machines

For the injection moulding plant we decided to purchase fully electric FANUC injection moulding machines equipped with linear robots, sorting flaps and conveyor belts. These machines guarantee high precision and repeatability of the production process, plus energy efficiency and reduced noise. That is why we purchased 4 machines with clamping force - 50, 100, 150 and 220 tons.

2019 - spotting press, mould storage

we have purchased a spotting press for easier mould adjustment in the toolshopfor mould storage we have purchased sliding racks with high load capacity

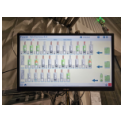

2019 - implementation of the new production planning system (MES)

We implemented a new production planning and control system (MES) - BMS Plantmaster + automatic data collection directly from the machines and input into ERP. This allows us to:

- see production in real time

- plan production more easily and efficiently

- react quickly to possible shortages

June 2018 - 4 new Engel machines arrived

to guarantee sufficient capacity we have purchased machines with clamping forces of 50t, 80t, 220t and 400twe now have a total of 27 machines - 35-500t

December 2017 - Engel 400t + assembly tables

we have increased our capacity for the production of larger parts - Engel 400twe have purchased new assembly tables for assembly

October 2017 - Engel 160t + assembly hall preparation

we have purchased another Engel machine - with clamping force of 160tpreparing the assembly hall for the new project and relocation from the existing facility - new floor + racks

June 2017 - third HERMLE machining centre

three-axis machining centre especially for machining of plates

February 2016 - recertification of IMS system

ISO 9001, ISO 14001, ISO TS 16949 - certified by TÜV Nord

May 2015 - new lathe for toolshop

we bought a new lathe for our toolshop

December 2014 - finishing the building + moving the first machines

the interior is already complete, the fire extinguishing agents in placeHermle C12 and Hermle C42 machining centres installedThe EOS P396 3D printer is also already in place29.12.2014 - FINAL APPROVAL

October 2014 - building progress

the interior is starting to take shape

August-September 2014 - building progress

the "rough construction" is almost finished

July 2014 - building progress

začalo se oplášťovat

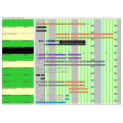

June 2014 - simulation program

we have purchased CADMOULD 7.0 3D-F injection moulding simulation software

- simulation of material flow into the mould including 2K and inserts

- shrinkage and deformation analysis

- analysis of cold joints, sinkholes, last filling point,...

June 2014 - building progress

construction starts to be assembled

May 2014 - building progress

the fundaments are coming to the finalsthe columns are starting to be prepared

April 2014 - building progress

reinforcement of fundaments

March 2014 - start of building of new storage, assembly hall and toolshop

reinforcement of fundaments

March 2014 - purchase of a new Engel victory 1350/220 injection moulding machine

latest controlincluding integrated linear robot

February 2014 - purchase of a new CNC 3D measuring machine Wenzel LH 87

latest generationstone table, bridge and pinola for more precise measurementsmax. measuring range: 800x1500x700mm

February 2013 - recertification of IMS system

certification by TÜV Nord

January 2013 - CAD workplace

we purchased a CAD workstation - Autodesk Inventorpart of this SW is also a module for filling study

May 2012 - air conditioning for the measuring laboratory

we installed 2 air conditioning units in the measuring laboratory to achieve 100% environmental stability

April 2011 - new machine 500t + central material drying & transportation

we installed a new injection moulding machine with a clamping force of 500tin line with the long-term plan, we successfully completed and launched the central material drying & transportation of PIOVAN

- improved material flow

- better overview

- reduced risk of mistakes (coded station)

2010 - automatization

we made additional steps to ensure process stability and production quality on larger machines with a higher volume of semi-automatic work and equipped 2 Battenfeld machines (200 and 270t clamping force) with linear robots

2010 - recertification

recertification of the integrated management system

2009 - central material drying & transportation

first part of the central material transport (Piovan mixing hoppers for the 2 largest machines)

2009 - relocation of assembly

we moved the assembly plant from rented spaces in Chlumec na Cidlinou to the previous injection moulding plant in Sopřeč

2008 - equipment for maintenance of tools

we have purchased equipment for the tool maintenance room

- lathe

- surface grinder

- stand drill

- saw

June 2007- 2K injection moulding machine ARBURG

we equipped the injection moulding plant with the first two-component injection moulding machineclamping force: 500 tdimension between bars: 920x920 mmvolume of the horizontal injection unit: 1608 cm³volume of the vertical injection unit: 154 cm³the machine is equipped with a 5-axis robot

end 2006 - beginning 2007 - ISO 14001 and ISO TS 16949 certification

in October 2006 the environmental management system was certified according to ČSN EN ISO 14001:2005in January 2007 the quality management system was certified according to ISO/TS 16949:2002 and DIN ISO 9001:2000

1.5.2005 - production started in the new injection moulding plant

=> the address changes to:UNIPLAST Pardubice spol. s r.o.Žáravice 61, CZ-533 16 Žáravice, Czech Republic

autumn 2004 - automatization of production

we purchased the first Geiger sprue pickups

end of August 2004 - start of construction of the new injection moulding plant

-> finish of construction - April 2005

May 2003 - certification according to ISO 9001:2000

migration to the new standard

end of 2002 - improvement of technology in the injection moulding plant

conveyors, inlet separators